WORDS BY LIKE THE WIND – PHOTOGRAPHY SUPPLIED BY ON

In his now famous 2005 commencement address to the students graduating from Stanford University, Steve Jobs told three stories. The first was about how the paths we take only make sense in hindsight. As Jobs said: “You can’t connect the dots looking forward; you can only connect them looking backward.”

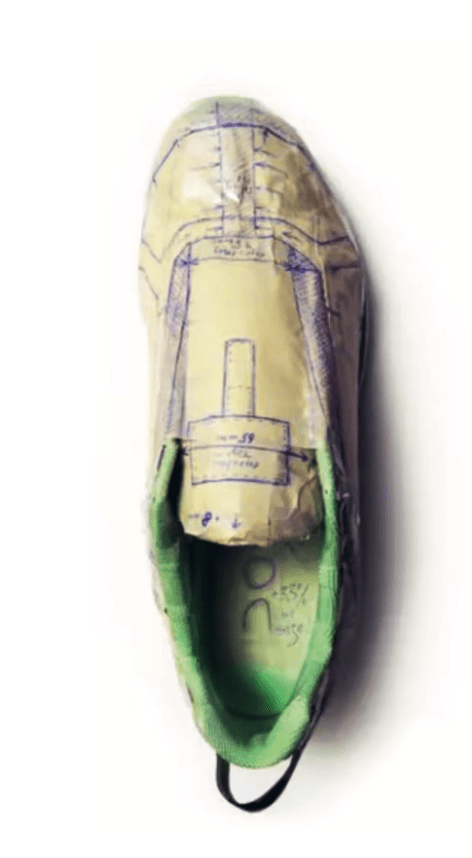

This idea sits at the heart of so much innovation. When Olivier Bernhard, a long-distance triathlon world champion, started to glue sections of garden hose to a pair of running shoes he was customising, he could not have known where his experiments would lead. So while the new On Cloudsurfer – which takes its name from the first shoe that On released in 2011 – seems like a logical progression, it is only because we are able to see where it has come from. Nevertheless, it does feel as though this shoe – developed thanks to free thinking and cutting-edge technology – could only come from On, a young brand with a storied past.

Nils Altrogge is On’s head of technology innovation. He joined in 2015 as the thirtieth employee (there are now over 1,800 people at On) at a time when the company was yet to make an impact on a global scale. But the ambition to create truly unique products was well established.

What has changed in the years since Nils joined the company is the level of technology upon which On is able to call to develop new products. In fact, the latest offering – the Cloudsurfer – is the embodiment of the way On operates at the cutting edge. In his current role, Nils works with a team who, between them, bring an array of knowledge and expertise to the process of product creation. One of those colleagues is Ben Lane, On’s simulation engineer in footwear innovation.

The starting point for developing new shoes at On always comes back to the basic principles of our sport: understanding how people run. Deep in the heart of the brand’s Zurich headquarters – inaccessible to all but a few key members of the staff – is a room dedicated to measuring runners. In the middle of the space is a top-of-the-range Rodby RL2000E treadmill, imported from Sweden, in front of which sits a huge screen, showing a video of a landscape (through which the runner can imagine they are moving) and a readout of multiple data points. These data points go far beyond the speed and distance commonly found on “regular” treadmills. It is a bewilderingly complex set-up, but one that gives On a clear advantage when it comes to imagining the future of running footwear.

To the left of the treadmill is a control station where Ben is able to monitor hundreds of parameters, generating vast volumes of data that have been fed into the prototyping software that was used to design the Cloudsurfer. Using data collected from hundreds of runners, Ben is able to generate virtual renditions of shoes, allowing testing to be undertaken without the need to make physical models (although, as we will see, that does happen later in the process). Using technology to test different versions of a new design means that thousands of iterations can be reviewed and tweaked to achieve the goals set for the shoe being created. This is not only more efficient from a time point of view, but also a far more sustainable way to test ideas and theories.

With the new Cloudsurfer, Ben and his colleagues used the software to engineer a completely new midsole using CloudTec PhaseTM technology, considering variables such as the different properties of the materials being considered, as well as the ways that bone, muscle and tendon actually respond to different loads and forces.

The next step is to take the designs from a virtual state into reality and see how the results of the data and computer prototyping can be refined further. And that’s a new way to design and create a shoe… but then it’s time to move into practicality.

This is where On’s Makers’ Space comes into play. Based across the courtyard from Ben and his colleagues, the Makers Space contains all the tools necessary to build an actual prototype of whatever Nils and his colleagues have designed virtually.

The process of crafting one-off prototypes is called “monster making” by the team of engineers in the Makers Space. Using 3D printing and sophisticated laser cutters, as well as blocks or sheets of the actual materials the designers have proposed for a new shoe model, a rough-looking but ultimately accurate replica of the shoe can be created in only a couple of hours, which allows the designers themselves – or athletes working with the On team – to take shoes for a test run.

Now the virtual design gets a real- life outing, giving Ben the opportunity to gather even more data with which to refine his designs.

Once a shoe has been through the virtual and in-real-life development process, there is the important process of bringing it to market – and making the manufacturing decisions that will ensure the product fulfils as many requirements as possible. In the case of the Cloudsurfer, that includes working out how to create a range of sizes that all deliver the same benefits. Of course, sustainability issues are at the heart of this process. One example of that is the decision to use a process called “dope dyeing” for the Cloudsurfer’s uppers – this severely limits the range of colours available, but saves huge amounts of water because the yarn, rather than the fabric, is dyed.

The original Cloudsurfer was released in 2011. At the time, it was a truly innovative and remarkable shoe. Based on Olivier Bernhard’s home-made prototype, the shoe announced On as a brand unconstrained by conventional thinking. More than a decade later and that mindset still drives everything that On does. The new Cloudsurfer is a great example of how a mindset can be combined with technology to create something completely new. The current iteration of the Cloudsurfer represents the best On has to offer.

Check out the On Cloudsurfer and the rest of the On range at www.on.com IG:@on_running