WORDS BY LIKE THE WIND – PHOTOGRAPHY SUPPLIED BY DIADORA

Housing research, development and production teams in the same factory creates an atmosphere where ideas can be bounced around and models can quickly be tested. Like the Wind editor Simon Freeman went behind the scenes at the Diadora HQ in northern Italy to find out more.

During the indoor athletics season, the 60m sprint is the blue ribbon event, holding the crowd’s attention in the same way as its longer sibling the 100m does outdoors. The difference is that the shorter race is over in what seems like the blink of an eye. At the Italian Athletics Indoor Championships, held in February 2023 in Ancona on the Adriatic coast, the winner of the men’s 60m race – Samuele Ceccarelli – covered the distance in just 6.54 seconds.

Around 250km north of Ancona, at Diadora’s headquarters and factory in Caerano di San Marco, Treviso, the distance between three crucial points in the creation of the brand’s revamped running shoe range is also about 60m. That could be called the distance of innovation. And ideas here move even faster than Ceccarelli.

Looking around the Diadora factory, it is striking how the process of making a pair of running shoes echoes the way shoes have been manufactured for generations. The space is lofty and cool, despite it being a warm, sunny day. Snaking throughout the factory is a production line; there is a wonderful rhythm to the way each pair of shoes is passed from hand to hand, from workstation to workstation, as they progress through the manufacturing process. Eventually, each pair of Diadora’s Made in Italy shoes is lovingly placed into a box, ready for the runner who will take them on innumerable adventures.

But that’s the end of the story. Let’s go back a bit. Or, in fact, forward about 60m.

Down that 60m corridor from the main factory floor is the Centro Ricerche Diadora (CRD). The research centre. A space packed with technology. At the door I am met by Michele Risatti, Diadora’s head of research and development – a man who is passionate and knowledgeable about the development of sports footwear.

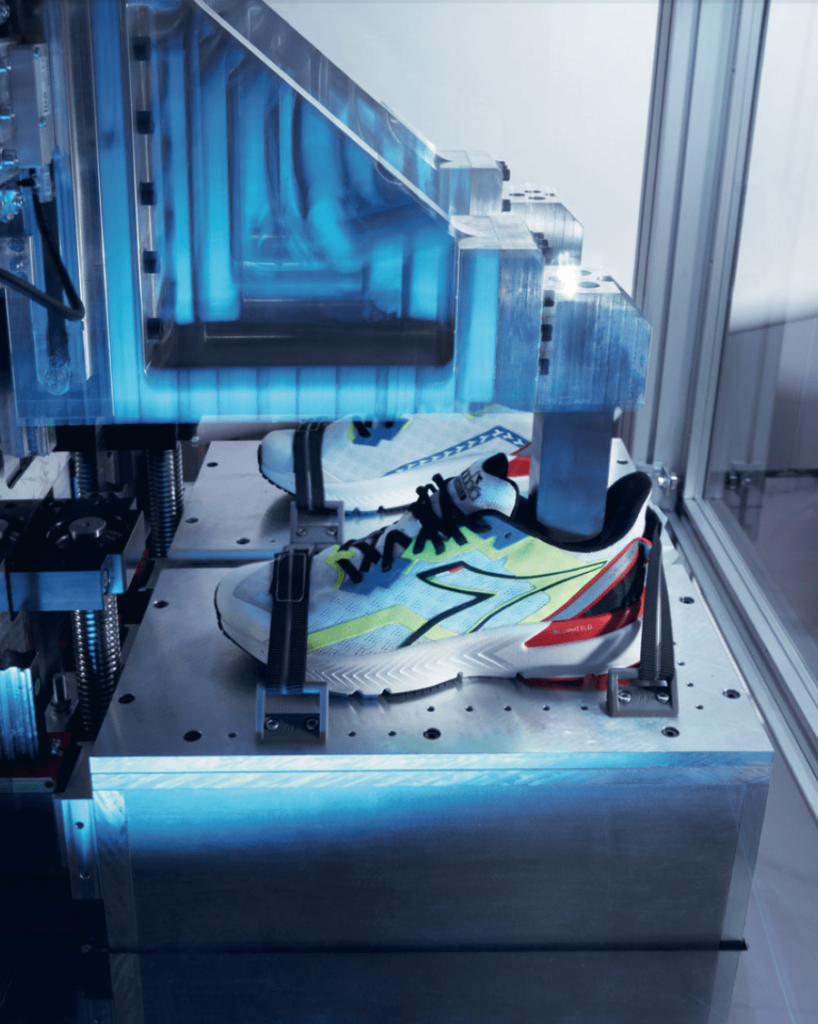

Michele believes that developing a great shoe comes from an understanding of how all the different elements in the shoe interact, not just with each other but also with the runner wearing them and the terrain. This requires detailed measurement and analysis of both components and entire shoes. But to achieve the level of insight Diadora requires, Michele and his colleagues had to start by creating the necessary tools. “Some years ago, we decided to develop machines that can measure all the aspects of a shoe,” explains Michele. “We needed to be able to properly measure cushioning, durability and so on in the materials used for our running shoes.”

One of the state-of-the-art machines in the CRD tests materials dynamically (rather than static testing, which is normal). The machine applies consistent force to a piece of midsole material as it deforms. This is important because a runner will apply the same downward force to his or her shoes from the day they take them out of the box until they finally dispose of them, but normal machines that apply force to test materials can’t adjust themselves as the material ages and record this data. The next machine Michele shows me is – appropriately – the R.A.C.E., which measures the energy rebound percentage of different midsole compounds.

On my way back to the factory, we pass another crucial part of the Diadora HQ: the product design department.

Here, former Olympic gold medallist Gelindo Bordin and his colleagues work with Diadora’s athletes to refine prototypes constructed in a special on-site facility. The athletes then test the shoes in real-life situations. A few steps past the product design department and I am back in the factory. Here Claudio Bora, Diadora’s CEO, ties together the three parts of the layout of the Diadora HQ and the process for me.

Claudio explains that Diadora started as a manufacturer of workers’ boots during the late 1940s. Right from the beginning, Diadora created its own high standards for the products it sold. The company has always created prototypes in-house, then rigorously tested them (and the finished products) to ensure quality is maintained. After three decades of growth, the company added sports shoes to its offering during the 1970s. The same focus on quality was applied.

Today, says Claudio, the Centro Ricerche Diadora, with its cutting-edge science, the product development team, working with athletes, and the factory, using traditional manufacturing processes, interact in a seamless way, all on one site. It is a model designed with quality and innovation at its heart.

On my way out, I pause in front of the HQ, adorned with huge hanging banners depicting some of the athletes Diadora has worked with and supported over the years. Something becomes clear about the reason that Diadora is determined to have the three parts of the manufacturing process in the same place. Because at the end of the day, proximity is the most efficient way to create the best products – those that deliver the maximum benefits to the runners that the brand serves. It is not complicated, but it is effective – Diadora simply fuses the old and the new in perfect harmony and at the speed of innovation.

www.diadora.com IG:@diadora